We recognise animals as sentient beings and as such we work with our perishables and Private Brand suppliers and our production units to encourage them to follow practices aligned with the five freedoms of animal welfare: i) freedom from hunger and thirst; ii) freedom from discomfort; iii) freedom from pain, injury or disease; iv) freedom to express normal behaviour; and v) freedom from fear and distress.

Based on these principles, we have established operating guidelines for our production units and applicable to all animal species we market, which can also be implemented for our perishable and Private Brand products in the countries where we have operations. The main guidelines include:

- prohibiting the use of growth promoters (growth hormones and beta-agonists);

- only using antibiotics for therapeutic purposes, never preventively or to promote growth;

- mandatory stunning of all animals before slaughter, with the exception of certified religious rituals, such as halal or kosher (accounting for less than 5% of total sales).

- banning animal testing in the product development processes, except for animal feed products (sensory tests are performed to assess the level of satisfaction of a specific target population) and products for controlling or eliminating parasites and/or super-populations that might be sources of contamination or disease (e.g. insects).

- banning the use of genetically modified or transgenic additives or ingredients, including cloning techniques, whether plant- or animal-based.

Our Policy on Genetically Modified Organisms1 (GMOs) states that Companies must:

- cooperate with suppliers to understand the production processes and assess their safety and quality standards;

- regularly carry out laboratory analyses, using independent and accredited entities;

- ensure that suppliers can identify and trace GMOs in the cases where they cannot be replaced;

- guarantee the consumers’ right to information about the presence of GMOs through product labelling2.

We conduct regular laboratory tests and food safety and quality audits, which include animal welfare criteria, of the suppliers and slaughterhouses used by our food distribution Companies in Portugal, Poland and Colombia to ensure compliance with these principles. Tests and audits are complemented by supplier training and awareness-raising initiatives. In 2024, the Group conducted over 2,060 GMO analyses in its Molecular Biology laboratory. For more information about these audits, see “Product analyses”.

These topics are also discussed at the Sustainability Committee meetings of each Company, where action strategies are discussed and performance goals set. The results are made public to enable progress to be monitored on the implementation of continuous improvement opportunities. Although it was not identified as a material topic in our double materiality matrix, we are committed with specific objectives to continue improving our animal welfare practices in the 2024-2026 period. Our animal welfare goals are described in subchapter 6 “Sustainability commitments” of this chapter. In 2024, and for the first time, in Poland and Portugal we conducted animal welfare audits of fresh aquaculture fish according to the “Fish Welfare” standard developed by Jerónimo Martins. We also achieved the goal of inspecting 100% of the fresh egg farms that supply the Biedronka Private Brand by the end of 2024.

For more information on these audits, the actions we develop with our suppliers and the outcomes achieved, see “Selection and monitoring of suppliers”.

Livestock transport and slaughter practices

In the countries where we have operations, we have implemented a monitoring system for perishables suppliers, focusing on indicators that allow us to assess animal welfare. For example, we portray animal transport conditions by monitoring the average duration of transport and the mortality rate during transport.

Portugal

Average travel time to the slaughterhouse in Portugal (hours) - perishables category

Mortality rate associated with the trip to the slaughterhouse in Portugal - perishables category

Taking into account the recommended maximum average journey time of 8 hours, in Portugal and since 2021 we have managed to keep journey time below this value and always below 4 hours.

The mortality rate has also remained below 0.25% in all animal species, suggesting that the animals are not subjected to excessive levels of discomfort, pain or suffering.

With regard to the practices of our perishable’s suppliers in slaughterhouses in Portugal, 100% of animals were stunned before slaughter and approximately 99% of stunning was effective at the first attempt (0.2 p.p. more than in 2023).

Colombia

Average travel time to the slaughterhouse in Colombia (hours) - perishables category

Mortality rate associated with the trip to the slaughterhouse in Colombia - perishables category

The year 2024 saw the first steps in our efforts to control and monitor key animal welfare indicators in Colombia. The average journey time for the three species we sell (beef, chicken and pork) was well below the recommended 8 hours (<4.5 hours).

The mortality rate associated with transport is around 0.6% in pigs, less than 0.15% in chickens and does not exist in cattle. These results suggest that the animals were not subjected to excessive levels of discomfort, pain or suffering during transport.

Poland

In Poland, we also assessed these indicators with our most representative suppliers for the first time in 2024. With regard to the average journey time, we are unable to report this information as we identified inconsistencies in the data collection.

Mortality rate associated with the trip to the slaughterhouse in Poland - Perishables Category

In 2025 we will improve our monitoring systems so that we can report this information next year.

The mortality rate was below 0.4% in all species.

Dairy, fresh egg and meat production practices

In our Private Brand and perishables assortment, we have integrated animal-based products and ingredients in line with responsible production practices and guided by ethical and animal welfare principles. We believe in the importance of information and awareness, and as such communicate with our customers through product labelling, in-store communication, commercial leaflets, Company websites and social media.

Beef

In 2024, Pingo Doce continued to market Private Brand Angus beef with double antibiotic-free production and animal welfare certification (obtained according to the international benchmark Welfare Quality and bearing the Welfair™ label), as well as organic beef. In the latter case, we also ensure compliance with certification criteria such as access of animals to the outdoors, non-GMO feed, and grazing. Together, Angus beef and organic beef accounted for a 5% weight on sales in the perishable beef category.

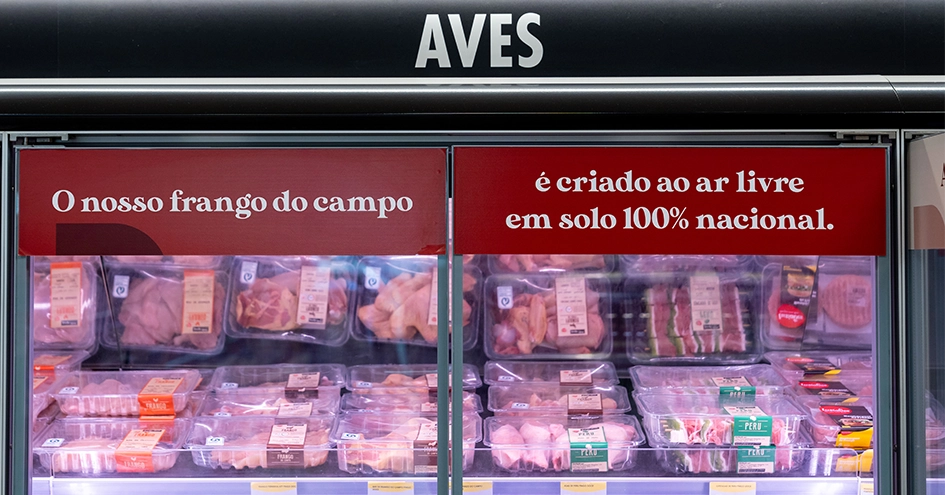

Chicken

Biedronka continued to sell its range of 100% nationally produced free-range chickens (Hubbard Redbro), raised antibiotic-free and fed GMO-free feed. The minimum slaughter age is 70 days (14 days more than the market average) and the chickens have access to the outdoors with a density below 27.5kg/m2, up to ten times more area than that of conventional chickens. Biedronka also continued to include 100% nationally produced antibiotic-free conventional chicken meat in its assortment.

At Pingo Doce and Recheio, free-range chickens are 100% produced in Portugal, have a minimum slaughter age of 81 days and are raised outdoors with a maximum density of up to 33 kg/m2. Both Companies continued to include Best Farmer’s Frango da Quinta chicken (Hubbard Redbro) in their assortment, which is mostly free-range and has an average slaughter age of 85 days. Production is certified antibiotic-free by AENOR and animal welfare certified according to the Welfair™ label (based on the international Welfare Quality benchmark). Thinning is not practised during production. Both free-range and Frango da Quinta chickens have access to the outdoors and natural light.

The sale of free-range chicken, animal welfare certified chicken and antibiotic-free chickens at Biedronka, Pingo Doce and Recheio have an 8% weight on sales in this category.

Dairy products

The Pingo Doce fresh milk range upheld the Welfair® label, which attests animal welfare certification according to the Welfare Quality protocol, issued by AENOR. The protocol is built on four basic principles: good feed, good shelter, good health and proper animal behaviour. This certification also assures that dairy cows are free from tethering and tail docking.

More than 95% of the producers who supply Terra Alegre’s dairy farm have maintained this certification.

Cage-free eggs

We remain committed to ensuring that all Private Brand fresh eggs come from uncaged hens by 2025. To facilitate the transition to cage-free egg production, the Companies have worked closely with their suppliers, including the search for new production sites and ensuring visits by our food safety and quality teams to ensure compliance with the required criteria.

In 2024, we maintained the 98% of fresh Private Brand eggs from uncaged hens. Pingo Doce reached the 100% target in August 2019. Biedronka did so at the end of 2022, having also extended its commitment to supplier brands. Ara does not offer Private Brand fresh eggs in its assortment. In addition, Ara, Pingo Doce and Recheio offer these options in their assortment via supplier brand.

Three cage-free hen production systems are accepted: barn, free-range and organic. These systems establish animal welfare criteria that reflect a better quality of life for these animals, with greater freedom of movement and providing them a greater possibility of expressing their natural behaviours than caged hens. Free-range egg production is the most widely adopted system.

Private Brand cage-free eggs by Company

PB Fresh Eggs' Production Systems - 2024

We are committed to ensuring that, by 2026, in Portugal and Poland, at least 90% of the eggs used as an ingredient in Private Brand products are from uncaged hens. At Biedronka, cage-free eggs have been used in 100% of the Private Brand assortment containing egg as an ingredient since 2022. Pingo Doce and Recheio continued to make progress in this regard, reaching 73% (12 p.p. more compared to 2023) and 41% (2 p.p. more compared to 2023) by the end 2024, respectively.

At Ara, and for the first time, we were able to monitor the Private Brand products that use eggs from uncaged hens as an ingredient, finding that cage-free eggs are used in 68% of the assortment.

Practices at Jerónimo Martins Agro-Alimentar (JMA)

JMA, which specialises in food production and supplies our distribution operations, has the following four business areas: dairy, livestock farming, aquaculture, and fruit and vegetables.

For more information about JMA, see “Agri-food”.

We follow standards that ensure animal welfare in the production of Aberdeen Angus beef. We provide an area of at least 6.5 m2 per animal, grooved concrete or rubber flooring to reduce the risk of slipping and getting hurt, and fresh straw for bedding every day, ensuring their comfort and well-being.

JMA has also implemented other animal welfare practices for Angus cattle:

- at least one bed per cow;

- 60 cm of feeder space per cow;

- access to automatic massage brushes and ambient music (to reduce stress);

- access to pasture areas for all animals;

- automatic cooling systems that activate fans and sprinklers to cool the animals, each with their own monitoring collar for the early detection of pathologies through behavioural changes, thus contributing towards a reduction in the use of drugs.

At our dairy farms and Angus production units, we also ensure:

- the vaccination and de-worming of 100% of animals;

- that no animals are subject to mutilation (e.g. tail docking and dehorning) and that they all have free movement (they are free from chains);

- automatic cooling systems that activate fans for ventilation and to reduce the amount of ammonia in the air;

- mandatory training in animal welfare for all employees in contact with the animals;

- that no electronic shocks, sticks or any system that may hurt the animals are used when moving or handling them.

In sheep production we ensure a minimum area of 0.6 m2 per animal, more than the recommended good practice of 0.5 m2, and feed based on forage (source of fibre) and concentrate. None of the animals are castrated and they all have freedom of movement.

In 2024, the JMA maintained its certification in the responsible use of antibiotics in beef production and dairy farm, ensuring that antibiotics are used only for therapeutic purposes. The Welfair™ animal welfare approved certification of these units was also renewed, in accordance with the European Welfare Quality benchmark. Sheep production is also Welfair™ animal welfare certified, based on the AWIN® benchmark.

We continue to ensure that 100% of fish (sea bass and sea bream) in our aquaculture operations are vaccinated. Production in open sea areas with constant currents guarantees good circulation and water quality. None of the animals are subject to mutilation (e.g. fin clipping). During slaughter, we use ice-cold water to rapidly cool body temperature to desensitise the animals.

1 Part of our Product Quality and Safety Policy, available on our website.

2 We ensure disclosure in strict compliance with the limit applied by the Group of a maximum of 0.1% (within the method's quantification limit). The limit allowed under European law is 0.9%.